The canvas products of Kobo HOSONO are handcrafted in all processes by several staff members.

The canvas products are hand-made one by one so that they are not only easy to use, but also strong and long-lasting, so that customers who use them will love them.

This time, I would like to introduce a part of the production process, using [ Rucksack SN ] as an example.

Canvas rucksack manufacturing process

Cutting of canvas fabric and parts

The canvas fabric, leather, etc., are cut accurately for each necessary part.

folding of canvas

Creases are made on the cut canvas fabric.

If you don't do this properly, the lengths will not match when you put each part together, so fold it accurately.

partial reinforcement

Reinforce the back and bottom parts of the main body that are likely to be subjected to force when held.By adding this process, it becomes possible to withstand considerable force.

Sewing each part

Sew additional parts such as zippers and pockets.

Processing of leather parts

Process leather parts such as the bottom and shoulder belts.

sewing on leather

Sew the parts to be reinforced with leather with a sewing machine.

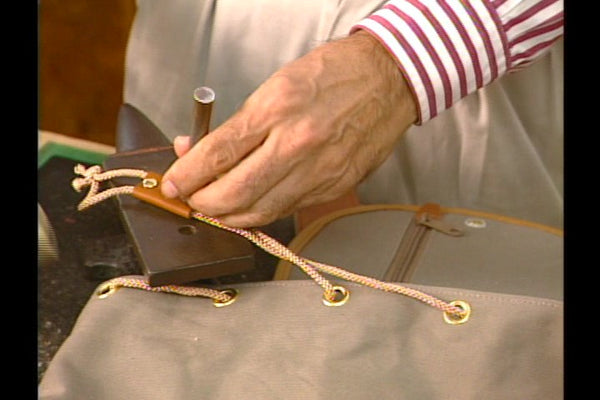

Hand-stitched reinforcement in areas where force is applied

The shoulder belt and other parts are the most stressed parts, so after sewing them on with a sewing machine, hand-stitch them again with linen thread to reinforce them.

body sewing

Sew the back part of the body. In the case of a rucksack, the most important part is the back, which is subject to a lot of force. I will finish it while checking each point.

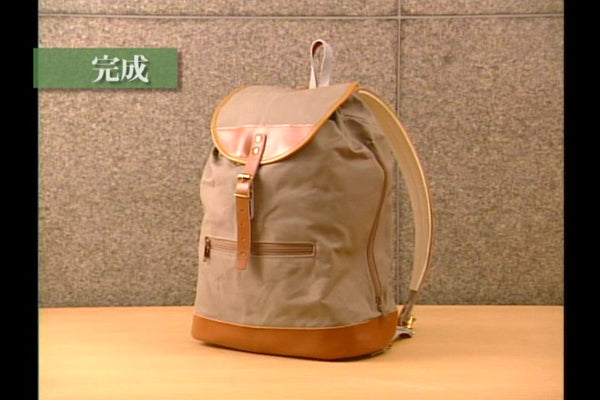

Backpack SN 45x32x14cm / 20L

That's all.

What I have introduced here is only a small part of the many production processes.

The production process varies depending on the product, but we are particular about making each item by hand through a number of other processes.